India is swiftly becoming a global powerhouse in the electronics manufacturing industry. With rising demand for smart devices, government-backed incentives, and a highly skilled workforce, electronics manufacturing companies in India are now competing at par with global giants.

The rapid growth of the electronics sector in India is driven by both domestic and international companies. Government initiatives like “Make in India” and “Digital India” have boosted the electronics manufacturing ecosystem, enabling the production of a diverse range of electronic products, from smartphones to consumer appliances.

As India continues to emerge as a major hub for electronics production, it’s essential to explore the key players driving this growth. This article will cover the top companies leading the manufacturing revolution, major manufacturing hubs, sector-wise growth, and future prospects.

Key Takeaways

- India’s growing significance in the global electronics manufacturing landscape.

- Rapid growth of the electronics sector driven by domestic and international companies.

- Government initiatives boosting the electronics manufacturing ecosystem.

- Diverse range of electronic products being manufactured in India.

- Competitive advantages offered by India as an electronics manufacturing destination.

The Rise of Electronics Manufacturing in India

India’s journey from being a net importer of electronics to a manufacturing hub has been remarkable, driven by initiatives like ‘Make in India’. Over the past decade, the country has transformed into a significant manufacturing hub, driven by government policies and rising consumer demand.

Government Initiatives Boosting the Sector

The Indian government has introduced several initiatives to boost the electronics manufacturing sector. Programs like “Make in India,” Production Linked Incentive (PLI) schemes, and “Digital India” have been instrumental in attracting investments. These initiatives offer tax benefits, subsidies, and infrastructure support, creating a favorable environment for electronics companies to scale their operations.

| Initiative | Benefits |

|---|---|

| Make in India | Tax incentives, infrastructure support |

| Production Linked Incentive (PLI) schemes | Financial incentives based on production output |

| Digital India | Enhanced digital infrastructure |

India’s Growing Position in Global Electronics Market

India is now the world’s second-largest smartphone market, driven by rising income levels, digital adoption, and smart technology penetration. The demand for mobile devices, TVs, wearables, and IoT solutions has fueled the growth of the electronics manufacturing industry. As a result, India is positioning itself as an alternative to China in the global electronics supply chain, particularly with the “China Plus One” strategy adopted by many multinational companies.

The growth of the electronics manufacturing services (EMS) sector in India has created a complete ecosystem from design to production, further solidifying the country’s position in the global electronics market.

Why India Is Becoming an Electronics Manufacturing Hub

With its vast pool of engineers and technicians, India is emerging as a preferred destination for electronics manufacturing. The country’s strategic advantages, including a skilled workforce, favorable government policies, and a growing domestic market, are driving this growth.

Skilled Workforce and Technical Expertise

India boasts a massive pool of engineers, technicians, and designers specializing in electronics, embedded systems, and automation. This technical expertise supports not just manufacturing but also research and development activities in the electronics sector.

Production Linked Incentive (PLI) Scheme

The Production Linked Incentive (PLI) Scheme has been a significant booster for electronics manufacturing in India. By offering financial incentives based on production volumes, the scheme has encouraged global brands to set up manufacturing units in the country.

China Plus One Strategy Benefits

As global trade tensions escalate, companies are adopting the “China Plus One” strategy to diversify their supply chains. India is benefiting from this trend, attracting investments from global electronics manufacturers looking to reduce their dependence on China.

| Key Factors | Benefits to India |

|---|---|

| Skilled Workforce | Supports manufacturing and R&D activities |

| PLI Scheme | Financial incentives for increased production |

| China Plus One Strategy | Attracts foreign investment and boosts exports |

Top 10 Electronics Companies in India

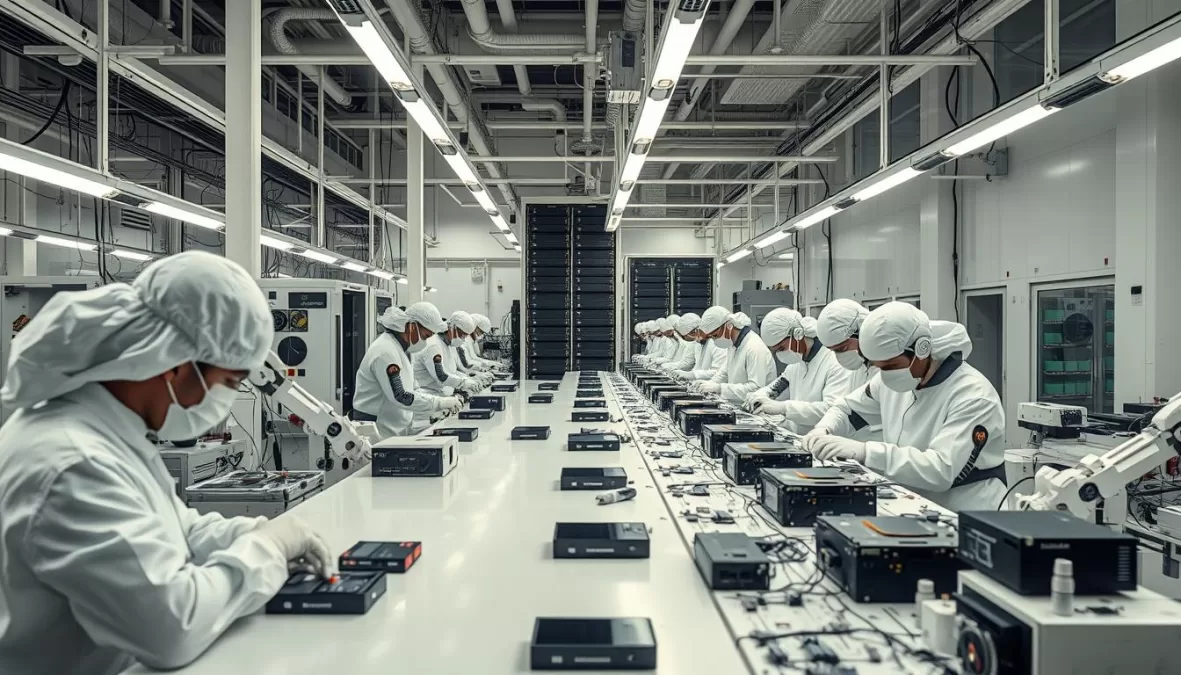

The top 10 electronics companies in India are transforming the country’s electronics manufacturing landscape. These companies are not only contributing to the country’s economic growth but also making India a hub for electronics manufacturing.

Samsung Electronics India

Samsung Electronics India is one of the largest electronics manufacturing companies in India, with a massive facility in Noida that is one of the world’s largest mobile phone manufacturing units. The company has a diverse product portfolio that includes smartphones, home appliances, and consumer electronics.

Foxconn India

Foxconn India is a leading manufacturer of iPhones and other electronic devices in India, with major facilities in Tamil Nadu and Andhra Pradesh. The company is planning to expand its operations in semiconductor assembly, further boosting India’s electronics manufacturing capabilities.

Dixon Technologies

Dixon Technologies is India’s homegrown success story in electronics manufacturing services, offering contract manufacturing for mobile phones, TVs, washing machines, and more for global brands like Samsung, Motorola, and Xiaomi.

Bharat Electronics Limited (BEL)

Bharat Electronics Limited (BEL) is a critical player in India’s defense electronics ecosystem, specializing in radars, communication systems, and aerospace-grade electronics.

Tata Electronics

Tata Electronics is preparing to build India’s first semiconductor manufacturing plant, marking a significant milestone in the country’s electronics manufacturing journey.

VVDN Technologies

VVDN Technologies combines product design and manufacturing capabilities, particularly in emerging areas like IoT, 5G, and cloud computing.

LG Electronics India

LG Electronics India has highly automated manufacturing bases in Ranjangaon and Greater Noida, with a strong presence in consumer electronics and home appliances.

Flex India

Flex India provides electronic manufacturing services for diverse sectors including medical, communications, automotive, and industrial applications, adhering to global standards.

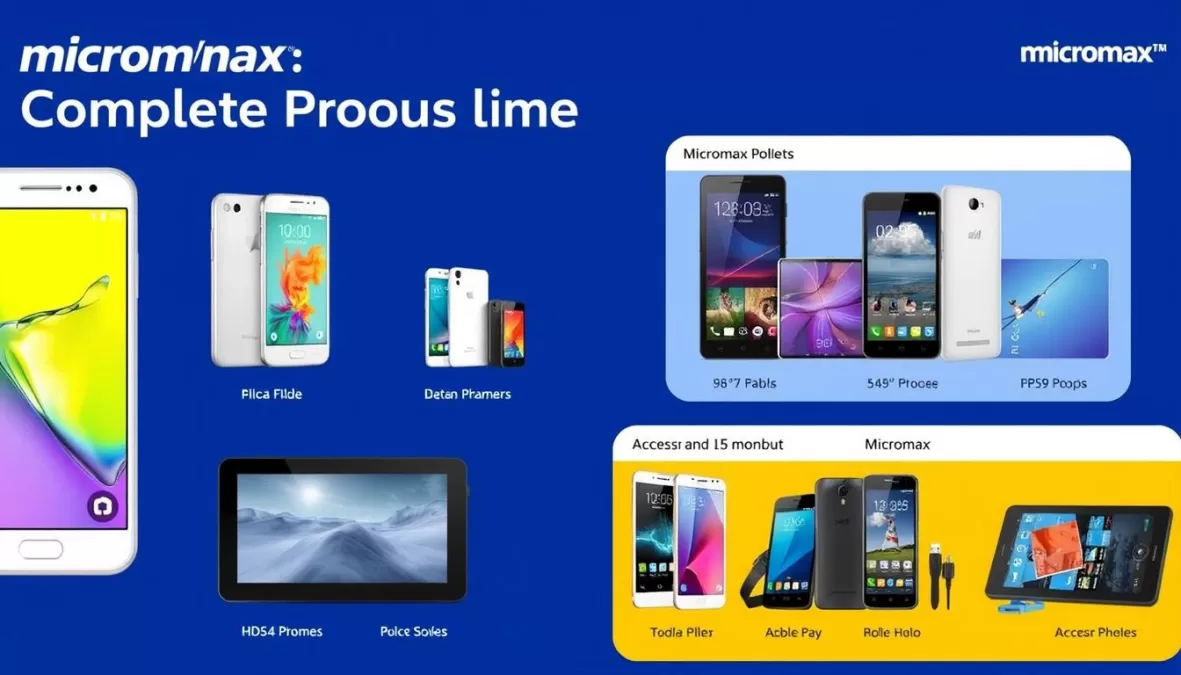

Micromax Informatics Ltd

Micromax is an Indian-based electronics manufacturer specializing in mobile phones, smartphones, and home appliances, competing with global players in the consumer electronics space.

Havells India Ltd

Havells India Ltd specializes in producing and distributing a broad range of electronic products including fans, lighting solutions, air purifiers, and water heaters.

Key Electronics Manufacturing Hubs in India

India is home to several key electronics manufacturing hubs that are driving the country’s growth in the sector. These hubs are crucial for the development of the electronics industry, providing a range of services from design to assembly.

Bangalore: India’s Silicon Valley

Bangalore, known as the “Silicon Valley of India,” is a major hub for high-tech electronics design and embedded systems. The city is home to a large number of IT enterprises and research institutions, creating a comprehensive ecosystem for innovation.

Noida and Chennai: Mobile Manufacturing Centers

Noida is a significant center for mobile phone manufacturing, hosting facilities of global giants like Samsung, Vivo, and OPPO. Chennai specializes in automotive electronics and consumer appliances, with companies like Foxconn establishing major operations.

Other Emerging Electronics Manufacturing Cities

Cities like Hyderabad, Pune, and Coimbatore are emerging as new electronics manufacturing centers, leveraging their unique advantages and specializations. These cities are supported by local educational institutions, providing a steady stream of skilled workers.

Sector-Wise Growth in Indian Electronics Manufacturing

As India’s electronics manufacturing ecosystem expands, different sectors are emerging as key growth drivers. The country’s electronics manufacturing industry is becoming increasingly diversified, with significant contributions from various segments.

Consumer Electronics Segment

The consumer electronics segment is witnessing substantial growth, driven by the increasing demand for products like televisions, air conditioners, washing machines, and kitchen appliances. Companies like Dixon Technologies and Elin are playing a crucial role in this growth, manufacturing these products domestically through Electronics Manufacturing Services (EMS).

Smartphones and Mobile Devices

The production of smartphones and mobile devices is another area where India is making significant strides. Global brands like Apple, Samsung, and Xiaomi are assembling millions of units annually in the country. In 2023, India exported over $15 billion worth of mobile phones, highlighting the sector’s export potential.

Defense and Automotive Electronics

Defense and automotive electronics are also emerging as critical sectors. Companies like Bharat Electronics Limited (BEL) are developing mission-critical electronic systems domestically, reducing import dependency. The growing demand for electric vehicles and smart mobility solutions is driving the need for sophisticated in-vehicle electronics.

Challenges and Future Prospects for Electronics Companies in India

The electronics manufacturing industry in India faces several challenges that impact its growth and global competitiveness. Despite these challenges, there are promising future prospects driven by government initiatives and growing demand.

Supply Chain Constraints

India’s electronics manufacturing is heavily dependent on imported components and raw materials, creating vulnerabilities in the supply chain. Global supply chain disruptions, like those experienced during the pandemic, have exposed weaknesses in India’s electronics manufacturing infrastructure.

Semiconductor Manufacturing Gap

India lacks large-scale semiconductor fabrication facilities, forcing manufacturers to rely on imports. Companies like Tata Electronics are planning to establish India’s first semiconductor manufacturing plant, addressing this critical gap.

Future Growth Opportunities

The Production Linked Incentive (PLI) scheme is expected to attract significant investments in electronics manufacturing. Emerging areas like 5G equipment, electric vehicle components, IoT devices, and renewable energy electronics represent new frontiers for Indian electronics manufacturers.

| Challenges | Impact | Mitigation Strategies |

|---|---|---|

| Supply Chain Constraints | Delays and increased costs | Diversify suppliers, invest in local manufacturing |

| Semiconductor Manufacturing Gap | Dependence on imports | Invest in domestic semiconductor fabrication |

| Infrastructure Limitations | Reduced manufacturing efficiency | Improve infrastructure, logistics, and power supply |

Conclusion

With global giants and local players leading the way, India’s electronics manufacturing industry is thriving. The top 10 electronics companies in India have driven innovation, employment, and economic growth, making India an attractive destination for electronics manufacturing services.

India is poised to become a global leader in electronics manufacturing, with a growing focus on design manufacturing and moving up the value chain. This growth contributes to India’s goals of self-reliance and a $5 trillion economy.